Micro Analytical Characterization of Cement and Engineering Materials (MACCEM)

The MACCEM laboratory is equipped with an Isothermal calorimeter, Mercury intrusion porosimeter, Particle size analyzer, Scanning electron microscope, and other facilities, for studying the hydration and microstructural development in a cementitious system.

Adiabatic Calorimetry

Temperature of the sample surroundings is maintained at the same temperature level as that of sample to prevent heat loss from the sample. The adiabatic calorimeter is used to monitor the temperature profile in concrete.

APPLICATION

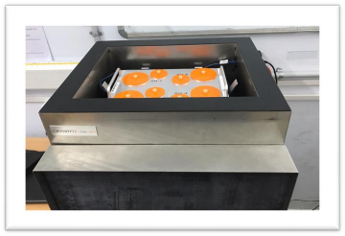

Isothermal Calorimetry

Isothermal calorimeter measures the heat released during cement hydration at constant temperature. I-Cal 4000 HPC from Calmetrix can be used to monitor 4 samples (up to 125 ml) simultaneously. The equipment facilitates the testing of cement past, mortar, and concrete.

APPLICATION

The calorimeter is used to measure the heat of hydration and the applications can be extended to compatibility of admixtures, sulfate optimization, the hydration kinetics, and their sensitivity to temperature.

Mercury intrusion porosimetry (MIP)

Mercury intrusion porosimetry (MIP) is based on the premise that a non-wetting liquid will only intrude capillaries under pressure. The relationship between the pressure and capillary diameter is described by Washburn equation.

APPLICATION

MIP is used to determine pore size distribution and total porosity of cement- based materials. It can be used to evaluate the durability of concrete systems.

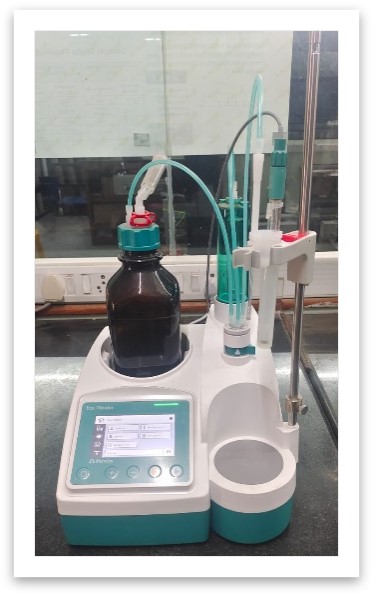

Pore Solution Extraction Device

Under high compressive stresses, pore solution from hardened cement paste can be extracted. Chemical composition of pore solution can be measured to understand the hydration of cement- based materials.

APPLICATION

The composition of pore solution can be used to study the influence of mineral and chemical admixtures on pore solution chemistry which directly affects the properties. Moreover, it can be used to determine the change in pH of pore solution.

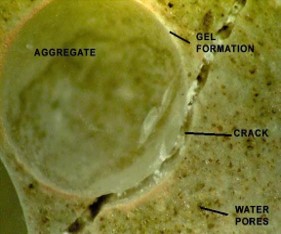

Optical Microscopy

Light optical microscopy offers the topographical and structural characterization of a variety of sample surfaces using visible light and an array of lenses.

APPLICATION

Optical micrographs can be used to study the surface features of raw materials and cement clinker, mineral phases, ASR, voids, crack pattern.

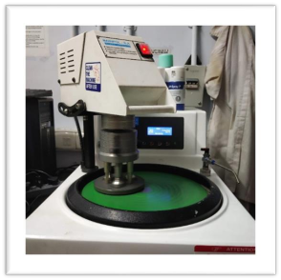

Sample Preparation Unit - SEM

Sample preparation for microstructure examination (imaging and chemical composition) of cement-based materials involves epoxy- impregnation followed by surface polishing. Epoxy-impregnation is performed under vacuum and useful in offering support to microstructure during polishing.

APPLICATION

The polishing unit can be used to prepare various materials including raw materials, hydrated cement paste, brick, stone, and concrete.

Scanning Electron Microscopy

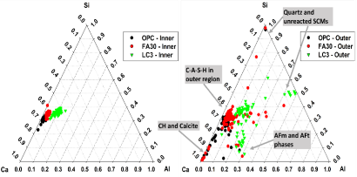

Interaction of electron beam and sample provides information to determine surface topography and composition of sample. EmCrafts Genesis 2000 coupled with Oxford energy-dispersive X-ray (EDX) spectroscopy device is available for microscopic imaging and chemical composition analysis.

APPLICATION

SEM coupled with EDX can be used for morphological and backscattered imaging of raw materials and hydrated cement matrix along with determination of chemical composition.

Handheld X-Ray Fluorescence (XRF)

Portable XRF analysis depends on the fundamental principles of electron beam and x-ray interactions with solid materials. When an electron moves from a high energy orbital to a lower energy orbital, energy is released in the form of X-rays that are characteristic of the type of atom present. Continuous ionization of the sample and absorption of energy from the incident beam allows for analysis of the complex X-ray spectrum emitted by the excited material.

APPLICATION

Handheld XRF provides ultimate quality of measurement within a couple of seconds. It gives highly accurate elemental analysis in a variety of applications like Alloy detection, mining and exploration, soil and sediment etc.

CO2 sequestration reactor

Both dry and wet carbonation can be performed with a pressure range of 1 to 50 bar and a temperature range of 50 °C to 200 ° C. The CO2 gas is fed to the chamber and the change in pressure and temperature is monitored using digital acquisition system.

APPLICATION

The chamber is used to cure the samples under CO2 atmosphere with various operating conditions. The CO2 uptake potential of material can be determined.

Scanning Electron Microscopy

working

Interaction of electron beam and sample provides information to determine surface topography and composition of sample. EmCrafts Genesis 2000 coupled with Oxford energy-dispersive X-ray (EDX) spectroscopy device is available for microscopic imaging and chemical composition analysis.

APPLICATION

SEM coupled with EDX can be used for morphological and backscattered imaging of raw materials and hydrated cement matrix along with determination of chemical composition.

Laboratory for Mechanical Performance of Civil Engineering Materials (MPCEM)

MPCEM laboratory facilitates the assessment of the mechanical performance of wide range of Civil Engineering materials including new composites such as textile-reinforced concrete. The MPCEM serves as a leading platform for industrial consultancy, sponsored and academic research. The compressive strength, tensile strength, flexural strength, shear strength, elastic properties etc. are evaluated at this laboratory.