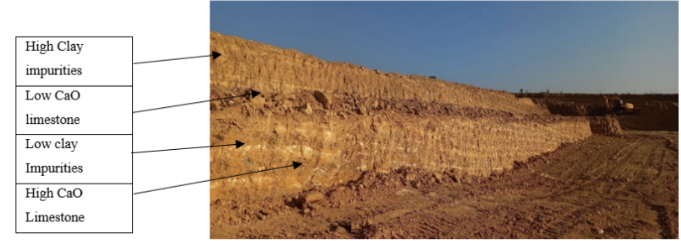

Management of the low grade limestone resources in mines where limestone is extracted for cement production is not only costly but such material also occupies precious land. This project provides an innovative solution for converting low grade resources into value added products which can be utilized in concrete, a material consumed in bulk quantities. The viability of the low grade limestone reserves in the different limestone mines in the country will be established in this project, which will lead to identification of the best processing techniques to make the material usable as a mineral additive in binary and ternary cementitious systems.

MoHUA launched ‘Global Housing Technology Challenge-India (GHTC-India)’ to promote new technologies in the construction sector. IIT-Madras was selected to set up an incubation centre along the lines of the ASHA scheme, in order to support two potential future technologies, namely (i) 3D printing in construction (M/s Tvasta Manufacturing Solutions Pvt Ltd) and (ii) 3D volumetric precast technology design (M/s Slabs Engineering Pvt Ltd).

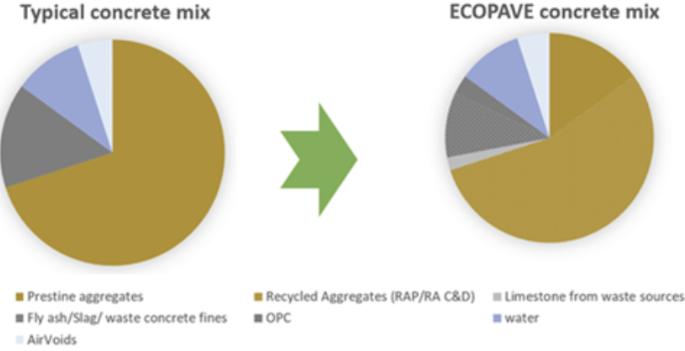

Rigid pavements are long-lasting and preferable. However, high volume utilization of natural materials makes this choice unsustainable and expensive. The use of construction, demolition, and industrial wastes can induce sustainability and economic benefits in rigid pavements. This project explores the potential of locally sourced waste streams in India and Germany to be used as constituents in concrete replacing both Portland cement and natural aggregates in high volumes at the same time. Scientific knowledge on microstructure and properties of concrete with such high volume of waste materials will be developed to address key challenges such as processing of waste, activation of waste materials (carbon and thermal activation), dimensional stability (creep, shrinkage, and curling) and durability (Alkali-silica reaction, freeze-thaw, and leaching). Mechanistic models will be developed to enable design of pavements utilizing such materials and a holistic machine learning based mix design framework which also considers life cycle assessment developed will help to maximize use of locally sourced waste streams. The final demonstrator will ensure the field applicability of the developed framework with an aim to

reach TRL6 at the project end. The partnerships established in this project between academic institutions and industry in India and Germany will lead to a long-term impact on the practice of sustainable construction and also in drafting the policies to enable the same.

Agricultural residues are widely available in India, providing a promising alternative for bioenergy generation. Use of these residues by micro, small and medium enterprises (MSMEs) for power generation leads to a significant ash generation. High volume utilization of biomass ash (BA) in alternative binders is of significant importance in reducing the carbon footprint of construction materials. This project aims to develop novel Portland cement-free alternative binders that use high volume of biomass ash (BA) in their formulations. First step will involve waste mapping across India. Subsequently, a detailed material characterization of biomass ashes will be carried out.

Thermo-mechanical methods to enhance the reactivity of biomass ashes will be examined. Effort will be directed toward establishing composition-reactivity relationship of biomass ash. In the next step, three techniques: 1) in-situ caustification, 2) one-part geopolymerization, and 3) hydrated lime and alkali activation, will be adopted for binder formulation. Binder attaining required strength and durability will be selected for further characterization. Advanced techniques including Field emission Scanning Electron Microscopy and Solid State Nuclear Magnetic Resonance (NMR) will be utilized to study the polymerization and modification in the structure of silica gel. This will provide strong evidence of the formation of poorly polymerized calcium silicate hydrate, partially polymerized silica gel, highly polymerized silica gel or geopolymer. This study involves an extensive molecular and microstructural characterization for a better understanding of new cementitious phases composed by calcium-modified silica gel, calcium carbonates, and calcium silicate hydrates. The effect of former on the engineering properties will also be explored to uncover potential applications. This project will open new avenues for high volume utilization biomass ash utilization in construction materials.

Elucidating the Role of Mineralogy, Aggregate-Mortar Bonding, and Comminution Mechanism on the Quality of Recycled Concrete Aggregates for Rigid Pavement Applications

India stands second globally in terms of Construction and Demolition (C&D) waste generation, however, the recycling capacity of all the plants put together is only 2.5%. Moreover, India is currently undergoing a severe shortage of pristine aggregates primarily due to an increase in infrastructure development and restrictions on mining activities. Numerous studies have been conducted in the recent past evidencing the

opportunity to extract high-value materials from C&D waste for high-end applications such as gravel, sand, filler materials, and

supplementary cementitious admixtures for concrete production, and even for cement production/replacement, etc. However, despite all these benefits, RCA is restricted to low-end applications; for rigid pavements, it is not even allowed for pavement-quality concrete slabs. Amongst different reasons, the presence of hydrated cement mortar paste (HCMP) around the aggregates has been found to be the root cause for the inferior quality of RCA and subsequently the quality of concrete systems containing RCA. However, there could be other dominating parameters controlling the quality & concentration of HCMP such as bonding between aggregate and mortar which may depend on the mineralogy & morphological characteristics of the aggregates and parent mortar composition mainly the hydration products, comminution mechanism adopted for recycling, and crushing energy chosen for breaking the waste concrete, etc. All these parameters may be interlinked with each other and therefore, their synergic impact on the quality of different fractions of RCA (coarse, fine, and concrete fines) and subsequently, the performance of paving concrete has to be studied fundamentally. The proposed project aims at comprehensively & fundamentally understanding these parameters and linking them with the behaviour of rigid pavements containing RCA. Initially, the aggregate-mortarinteractions will be understood through intermolecular and interfacial bond strength studies. The influence of

different mineralogies/lithologies of aggregates (limestone, sandstone, granite) and cement-mortar of varying compositions (M10-M80) on the bonding strength will be studied and delineated. Following this, the role of the comminution mechanism in affecting the physical-chemical-morphologies characteristics of different RCA fractions will be understood. Concrete fines, which have been recently discovered to have binding characteristics will be studied with regard to their potential to be used as supplementary cementitious admixture

and/or replacement for cementitious binder systems. The influence of parent concrete composition on the fresh, mechanical, and durability behaviour of rigid pavements will then be elucidated. Since all the dominating parameters of RCA recycling will be studied in this project, the findings could be useful in establishing a framework for extracting high-quality RCA for different high-end applications.

Elucidating the Role of Cement-Asphalt-Aggregate Interaction on Failure and Durability of Rigid Pavements containing Reclaimed Asphalt Pavement Aggregates

The proposed project aims at a comprehensive behavioral understanding of RAP-concrete through two pivotal points:

experimental underpinning and theoretical predictions. The understanding on cement-asphalt aggregate interactions will

be made through intermolecular and interfacial bond strength studies. The effect of basic properties of RAP such as viscosity of adhered asphalt (μ), cement-mortar hydrated products (CSH), aggregate’s mineralogy (m), and the asphalt film thickness (t), on the bond strength (σ_b ) of RAP-concrete, will be studied and delineated. Following this, the mechanical and shrinkage behavior of RAP-concrete will be understood through laboratory studies. The strong experimental underpinning will then be used to check the efficacy of appropriate strength and shrinkage prediction models for RAP-concrete. Since all the possible combinations of asphalt, cement, and aggregates will be studied in the project, the findings could be useful in selecting the right RAP for concrete pavement application. Finally, guidelines for behavioral predictions of RAP-concrete will be furnished.

Framework for Optimizing and Enhancing the Performance of Concrete Pavements using Natural Coir Fibres (CoirCon)

Concrete pavements are superior to bituminous roads mainly due to their lower life-cycle cost and higher serviceability.

The only drawbacks associated with rigid pavements are their higher initial construction cost and longer curing periods; 28

days of water curing is required post one day of its construction. However, it has been widely seen that small cracks start appearing in the concrete pavements immediately after their construction. This distress is commonly known as plastic shrinkage cracks and occurs predominately due to evaporation of mixing water. It has been widely acknowledged that the use of synthetic fibres may arrest these cracks. The use of metallic fibres may even enhance the post-failure load-carrying capacity of pavements. However, these fibres are expensive and may lead to a further increase in the initial construction cost of concrete roads. In this project, an attempt will be made to explore the potential of coir fibres to arrest the plastic shrinkage cracks when used for rural concrete (CoirCon) roads. Also, its impact on other functional and structural

performance of concrete pavements will be studied through extensive laboratory as well as field investigations. Since coir

fibres may have inherent characteristics that may impact the concrete properties and thus, the ways in which the coir

properties could be improved will be explored in detail. It is expected that at the end of the project a methodology for

effective preparation of coir fibres for specific utilization in concrete pavements could be furnished. Also, efforts would be

made to furnish guidelines and protocols for the construction of CoirCon roads at the end of this project.

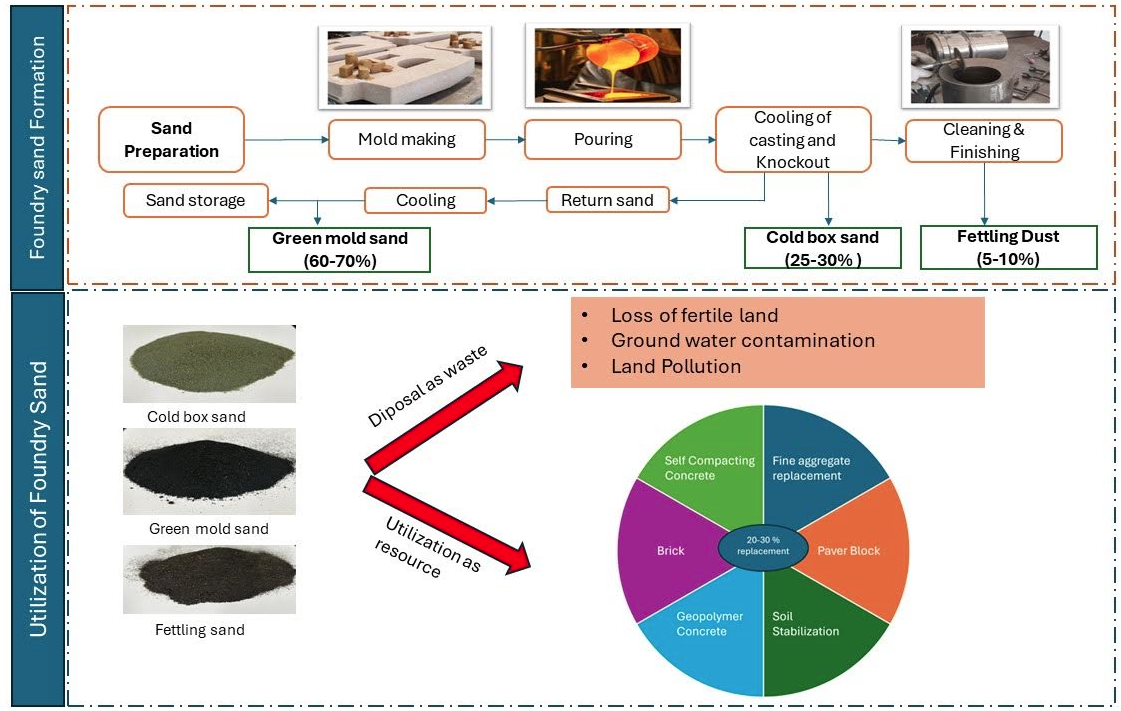

Automotive industries such as Yuken India etc. use a significant amount of sand for molding and casting operations. In general, pure silica sand is used in the presence of other materials due to its high-thermal resistance. For example, silica sand is mixed with bentonite clay and coal ash for molding purposes (known as green sand), whereas, resins and hardeners are mixed with silica sand for casting shell cores (known as chemically bonded sand). Typically, this mixture of sand is used multiple times but eventually has to be discarded due to degradation of its properties. This waste is called waste foundry sand (WFS). The quantum of WFS generation is huge in India; a survey conducted in Chennai shows 400 tons of WFS generation daily from two plants alone. Most of this waste is directly sent for landfilling purposes which is cost-intensive as well as have environmental concerns; the dumping cost may increase in the future due to an increase in the landfilling charges. In addition to a direct loss due to landfilling charges, storage of WFS occupies a significant plant area that could be used for other important purposes. Therefore, it is necessary to find alternative usage of the WFS rather than dumping which is the loss-making to the company. WFS can be used in the construction industry as evident from the literature. Good literature is available wherein WFS has been used in place of natural sand for various pavement applications such as concrete production, subgrade, etc. However, depending on the chemical and physical characteristics, WFS may be used for high-end purposes such as a filler material or even as supplementary cementitious material (SCM). It should be noted that fly ash (by-product from coal industries) was also considered to be a waste material; however, due to its pozzolanic characteristics, it is now considered to be an important ingredient for pavement & building construction. Therefore, it is necessary to study the physical and chemical composition of WFS and explore its true potential for different applications. This project aims to identify the potential of WFS for two main applications viz. subgrade/embankment/backfill materials and concrete manufacturing.