An Integrated Test-Bed for large-scale processes and visualization

A major part of the development is towards creating a test bed for technologies and ideas in the low-carbon and lean construction space. The test bed would not only serve to set up pilot scale assessments for research already carried out at IIT Madras but also be available for innovators and technologists to try out their own materials and formulations. The test bed consists of (i) a Pilot plant for using solar for the thermal treatment of recycled materials, (ii) Aggregate processing, (iii) Cementitious materials processing, (iv) Multi-scale characterization of concrete, and (v) an integrated mini batching plant with 3D printing facility

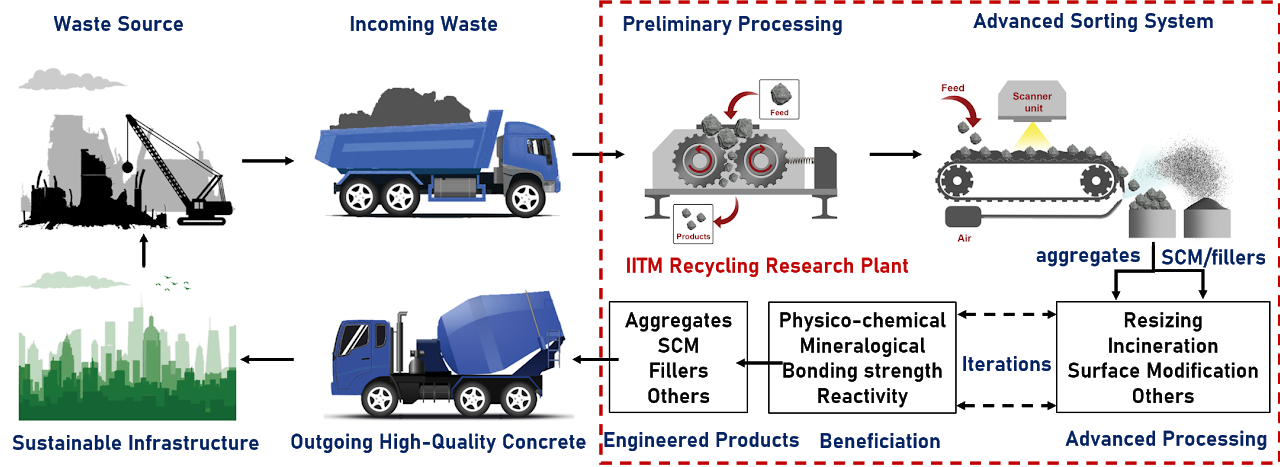

To enable the transfer of technologies to the field, we are also envisaging development of pilot scale testing facilities and visualization. We are setting up recycling test-bed for automated screening and physiochemical processing of various materials. The software and tools developed as part of our applied research will be implemented at this scale with machine-learning based optimization of the usage of recycled material in concrete structures.

Additionally, we are developing a AI-VR integrated testbed environment that will enable us to identify optimal use of materials, simulate and optimize construction practices and thereby reduce the carbon footprint of our future constructions. For such technological adoption we also need to understand? management adoption strategies, organizational training and specialty skill training on lean process. For this, we are developing along with the AI-VR, integrated simulation and game-based learning facility. With these facilities we enable the accelerated adoption of technologies.

Physical Test Bed

A major part of the development is towards creating a test bed for technologies and ideas in the low-carbon and lean construction space. The test bed would not only serve to set up pilot scale assessments for research already carried out at IIT Madras but also be available for innovators and technologists to try out their own materials and formulations. The test bed consists of (i) a Pilot plant for using solar for the thermal treatment of recycled materials, (ii) Aggregate processing, (iii) Cementitious materials processing, (iv) Multi-scale characterization of concrete, and (v) an integrated mini batching plant with 3D printing facility. Other salient features of the Physical test bed are –

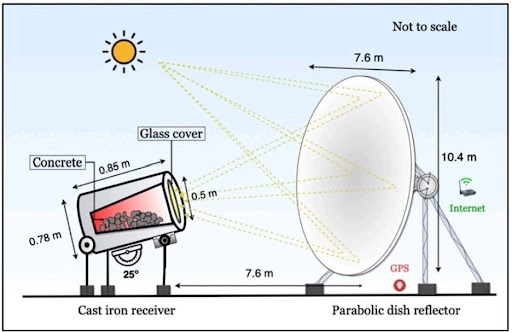

A. Pilot Plant for Solar-Enabled Thermal Treatment for Recycled Concrete Aggregate

The research team has already developed a beneficiation technique using concentrated solar energy to extract high-quality recycled concrete materials from waste concrete elements for various high-end applications such as gravel, sand, filler material, supplementary cementitious material, and even for cement replacement. This facility will be an industry-scaled version of the previously developed technique. This will be open for processing different wastes that need heating up to 500 degrees Celsius.

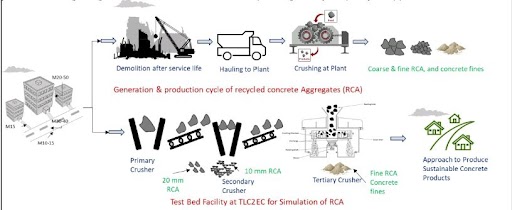

B.Testbed on Aggregate

The test bed on aggregates can effectively simulate the production of natural and alternative aggregates, such as C&D waste in laboratory conditions. It will consist of conventionally used primary, secondary, and tertiary crushers, sorting devices, and other facilities used in aggregate production plants. Industries can use this facility to optimize their crushing process for extracting recycled materials of desirable quality and for specific applications.

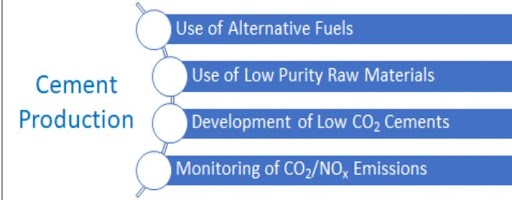

C. Testbed on cement production

The cement industry contributes to 7-8% of global CO2 emissions. The test bed for cement production would explore 1) utilization of alternative fuels (e.g., biomass) for cement production, 2) manufacturing of low CO2 cement, 3) utilization of low-purity materials (e.g., low-grade limestone, red mud) in manufacturing portland cement and special cement, and 4) monitoring the emissions (CO2/NOx) during cement manufacturing.

D. Sophisticated Instruments Lab, Mechanical and Durability Lab

Materials characterization is crucial in their effective utilization in construction materials. This facility will have a range of techniques: 1) to assess the physicochemical properties of waste materials (C&D waste, biomass ash, and other industrial byproducts), 2) to characterize the mechanical performance of the binders/composites made from the waste materials, and 3) to evaluate long-term durability of developed composites in an accelerated environment.

E. Integrated mini batching plant with 3D printing facilities

The mini-batching plant would enable industry-like assessment of new cementitious and aggregate types in concrete. All the required workability and rheology assessment equipment will be made available. Further, the 3D printing facility would have small and large-scale gantry printers and a mobile robotic arm printer for creating structural elements at different scales. A large panel test facility will also be created for structural testing of the 3D-printed panels.

Virtual Test Bed

F. Construction Process Visualization and Optimization Lab

The purpose of this facility is to enable scenario-driven decision-making for construction organizations to strategize their unique pathway to sustainable construction. The facility will enable the construction organization to: (1) Interactively visualize alternate construction processes and assess their impact on a project’s cost, quality, time, safety, and sustainability performance; (2) To learn about the role of human behavior in the pathway towards sustainability through simulation-based games; and (3) To benchmark and test indigenously developed digital technologies for their adequacy in the Indian construction sites. As shown in the figure below, we already have established such visualization experiences using Virtual Reality (VR) and its usage in training on various construction processes.

G. LCA Lab

For a genuine improvement in the sustainability performance of the construction industry, a life-cycle perspective through Life-Cycle Assessment (LCA) is necessary to quantify the effects of various innovations in materials, processes, management, and policy in terms of reduced carbon emissions. The LCA lab will serve three primary purposes (1) To create an India-specific LCA database through TLC2s research to enable the researchers and organizations across India to accurately assess their impact (2) To provide consultancy services for various organizations marching towards their paths to sustainability (3) To provide a platform for the construction industry to test the sustainability-related impact of their ideas. Services to the Indian industry could include developing and auditing Environmental Product Declarations (EPDs), improving processes and guidance on the choice of material/technology through LCA, and avoiding “green-washing.”

Representative images from previous research showcasing our work on creating LCA database

H. Policy and Contract Management Lab

Low carbon and lean construction research are aimed at the development of sustainable materials and practices in construction. When research efforts culminate into the final industry-ready product (or process), the next task will be the implementation. This challenge can be addressed by drafting effective policy and contract documents. The proposed policy and contract management lab will house state-of-the-art computing facilities and researchers working continuously towards tapping the Artificial Intelligence (AI) revolution to develop policy and contract documents to implement sustainable construction practices. In addition, the lab will also facilitate industry-academia-government discussions on the ongoing research at TLC2 and generate ideas to implement demonstrated technologies and processes at construction-based industries and project sites.